Sealing Surface Finish

Use 120-240 sandpaper that is fixed with tape on a thick glas plate.

Places the head or the cylinder with the sealing surface on the sandpaper. Press it softly and turn left and right 4 times. Reposition the workpiece by 90 degrees and do the same again. Perform this procedure until the workpiece is back in the starting position. This way you compensated the asymmetries of your movement

Important: The rotation needs to be centered by the central axis of the spark plug hole respectively the cylinder. Other whise you will end up in a unbalanced sealing surface.

Image: Surface unfinished (left) and micrograph finished (right)

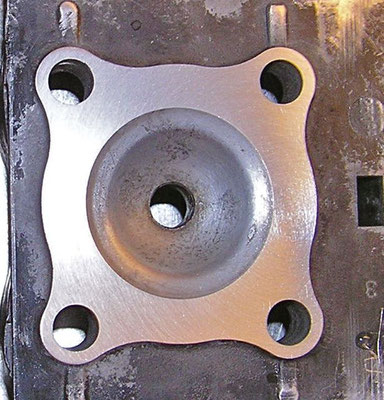

The surface will shows you if you are finished. If still dark spots are seen like in the picture on the left the sealing surface is not plane. Please make another pass. If the entire sealing

surface is blank like on the right you are finished.

Now the sealing surfaces are better than ever before. You can mount head and barrel without a gasket and it will be perfect tight. Lubricate the clean sealing surface before mounting with bearing

grease.

Hint: This method is only to improve the surfaces. Please do not try to mill more than of 0.1 mm or more. The sealing surface will become spherically.